En la industria moderna de logística y almacenamiento, las carretillas elevadoras son equipos indispensables, y seleccionar la batería de carretilla elevadora adecuada es crucial para garantizar su funcionamiento eficiente. Actualmente, existen dos tipos principales de baterías en el mercado: las tradicionales baterías de plomo-ácido y las emergentes baterías de fosfato de hierro y litio. Este artículo proporcionará una comparación detallada de estos dos tipos de baterías a través de datos y casos del mundo real para ayudarle a tomar decisiones informadas.

I. Descripción básica

Baterías de plomo-ácido:

Larga historia: las baterías de plomo-ácido han dominado el mercado desde finales del siglo XIX.

Bajo costo: Menor costo de compra inicial.

Altos requisitos de mantenimiento: es necesario un riego regular y una carga de ecualización.

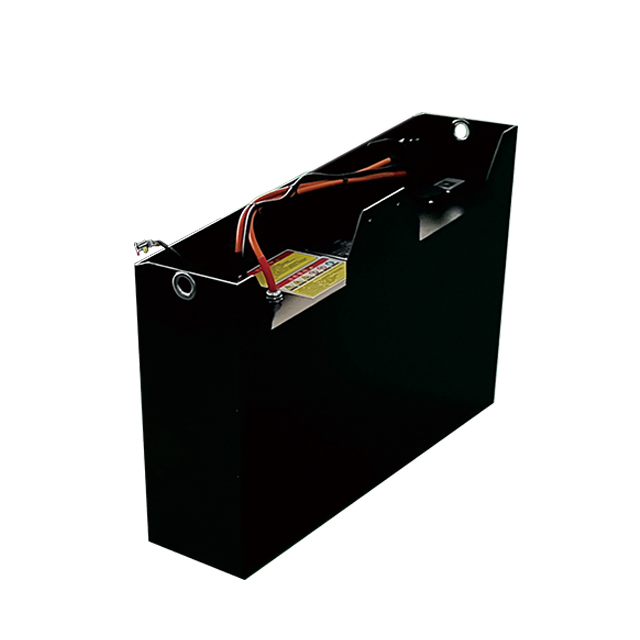

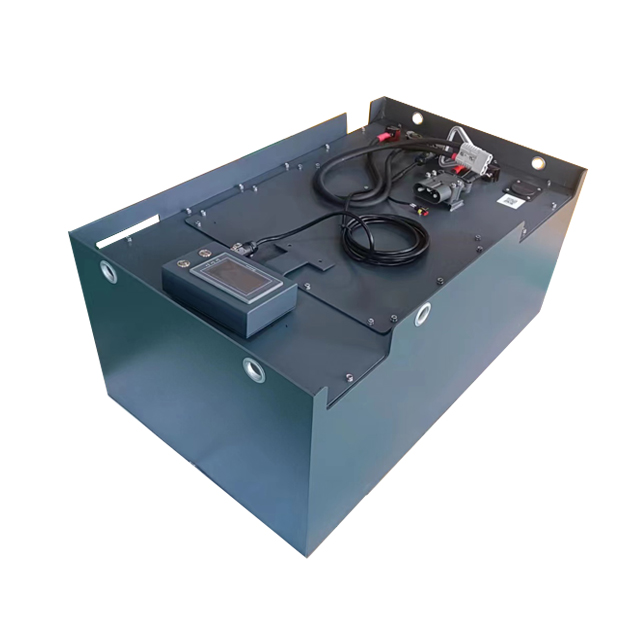

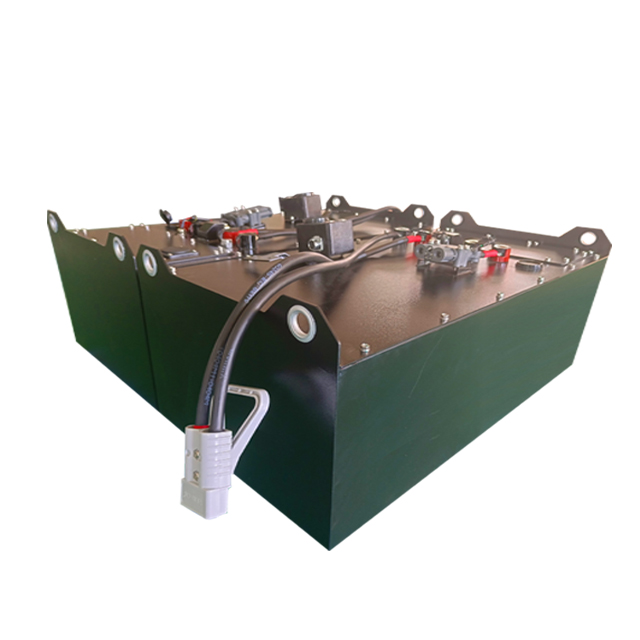

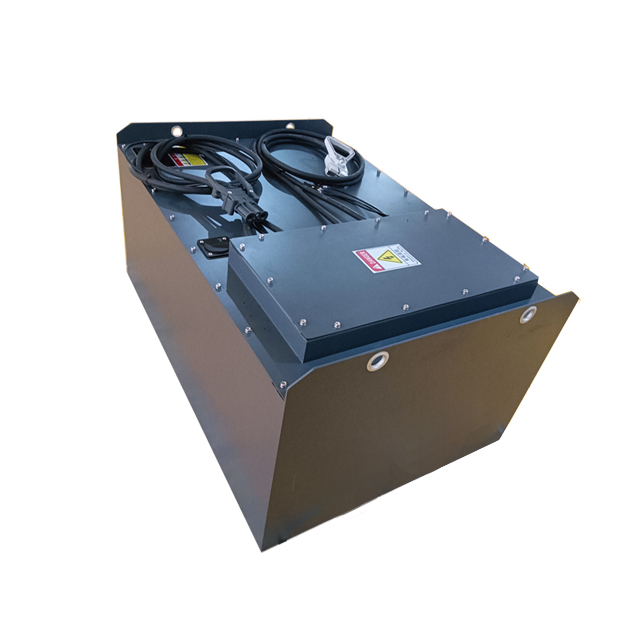

Baterías de fosfato de hierro y litio:

Tecnología emergente: Aplicada recientemente en la industria de montacargas.

Alto costo inicial: mayor costo de compra, pero menor costo total del ciclo de vida.

Bajo mantenimiento: Prácticamente sin mantenimiento y con una larga vida útil.

II. Comparación de rendimiento

Duración de la batería:

Baterías de plomo-ácido: normalmente clasificadas para 1000-1500 ciclos de carga y descarga.

Baterías de fosfato de hierro y litio: la vida útil puede alcanzar entre 3000 y 5000 ciclos de carga y descarga.

Eficiencia de carga:

Baterías de plomo-ácido: eficiencia de carga de alrededor del 70-80% y requieren de 8 a 12 horas para una carga completa.

Baterías de fosfato de hierro y litio: eficiencia de carga de alrededor del 95 %, normalmente cargadas por completo en 4 horas.

Densidad de energía:

Baterías de plomo-ácido: Menor densidad de energía, aproximadamente 30-50 Wh/kg.

Baterías de fosfato de hierro y litio: Mayor densidad energética, alrededor de 90-120 Wh/kg.

Adaptabilidad ambiental:

Baterías de plomo-ácido: Sensibles a las variaciones de temperatura, el rendimiento se ve afectado significativamente.

Baterías de fosfato de hierro y litio: rendimiento estable en un amplio rango de temperaturas, operativas entre -20 °C y 60 °C.

III. Análisis de costos

Según datos de una encuesta de mercado de 2022, el coste de compra inicial de las baterías de plomo-ácido es aproximadamente entre un 30 y un 40 % más bajo que el de las baterías de fosfato de hierro y litio. Sin embargo, considerando el costo total del ciclo de vida (incluidos los gastos de mantenimiento, el consumo de energía y la frecuencia de reemplazo), el costo total de las baterías de fosfato de hierro y litio es aproximadamente un 20 % menor que el de las baterías de plomo-ácido.

IV. Casos del mundo real

Estudio de caso 1: Elección de una empresa de logística

Una gran empresa de logística actualizó sus baterías en 2021, reemplazando las baterías de plomo-ácido por baterías de fosfato de hierro y litio. Los resultados mostraron:

Incremento del 20% en el tiempo promedio de operación de montacargas.

Aproximadamente un 50% de reducción en los costos de mantenimiento.

El consumo total de energía disminuyó un 15%.

Estudio de caso 2: Aplicación en la industria manufacturera

Una empresa manufacturera utilizó 200 montacargas equipados con baterías de fosfato de hierro y litio en su fábrica. Después de un año de uso, observaron:

Disminución del 30% en las tasas de fracaso.

El tiempo de carga de los empleados se redujo de 8 horas por día a 2 horas.

Mejora del 25% en la eficiencia de los montacargas.

V. Conclusión

A través de las comparaciones y los casos del mundo real presentados anteriormente, es evidente que, si bien las baterías de fosfato de hierro y litio tienen un costo inicial más alto, sobresalen en términos de vida útil, eficiencia de carga, densidad de energía y costos de mantenimiento en comparación con las baterías de plomo-ácido. Para las empresas que buscan rentabilidad a largo plazo y un funcionamiento eficiente, las baterías de fosfato de hierro y litio son sin duda la mejor opción.

Esperamos que esta comparación detallada en el artículo le ayude a tomar decisiones informadas al seleccionar baterías para montacargas. Si tiene más necesidades o preguntas, no dude en contactarnos para obtener un asesoramiento más profesional.

Español

Español