Los montacargas sirven como activos esenciales en numerosas industrias para tareas de manipulación de materiales, transformando el transporte de mercancías en la fabricación, el almacenamiento, la logística, el comercio minorista, la construcción y más. A medida que avanzamos hacia una nueva fase de la gestión de materiales, la evolución de las carretillas elevadoras se caracteriza por avances significativos en las soluciones de baterías de iones de litio. Estos avances garantizan una mayor eficacia, productividad, respeto al medio ambiente y viabilidad económica.

Elegir baterías de litio en lugar de plomo ácido: mejorar el rendimiento y la sostenibilidad de las carretillas elevadoras

Durante un tiempo considerable, las baterías de plomo-ácido han sido la opción preferida para las carretillas elevadoras eléctricas y ocupan una posición dominante en el mercado. Sin embargo, con las crecientes demandas de las cadenas de suministro globales, las industrias involucradas en el manejo de materiales deben optimizar las operaciones, reducir costos y garantizar entregas puntuales, todo ello teniendo en cuenta las consideraciones ambientales. Cuando se comparan con las soluciones tradicionales de baterías de plomo-ácido, las baterías de montacargas alimentadas por litio se enfrentan a estos desafíos de frente. Sus beneficios abarcan:

Densidad de energía superior: almacenar más energía sin aumentar el tamaño, lo que permite que los montacargas impulsados por litio maniobren con destreza en espacios operativos reducidos.

Carga rápida y conveniente: la ausencia del efecto memoria permite cargar durante los descansos y entre turnos, lo que aumenta la disponibilidad de los equipos y el tiempo de actividad para las industrias que ejecutan varios turnos al día.

Estabilidad de rendimiento constante: mantener un voltaje estable en todos los niveles de descarga garantiza un rendimiento inquebrantable sin caídas repentinas de energía.

Ambientalmente seguro: libre de sustancias peligrosas, lo que promueve la seguridad y el respeto al medio ambiente. Elimina la necesidad de salas de baterías dedicadas y equipos HVAC.

Requisitos mínimos de mantenimiento: elimina la necesidad de recargas periódicas de agua y controles diarios, y elimina la necesidad de desconectar la batería para recargarla, reduciendo así el cambio de batería, la frecuencia de mantenimiento y los costos de mano de obra.

Vida útil prolongada: con un ciclo de vida prolongado, una sola batería puede alimentar operaciones de manera confiable durante muchos años.

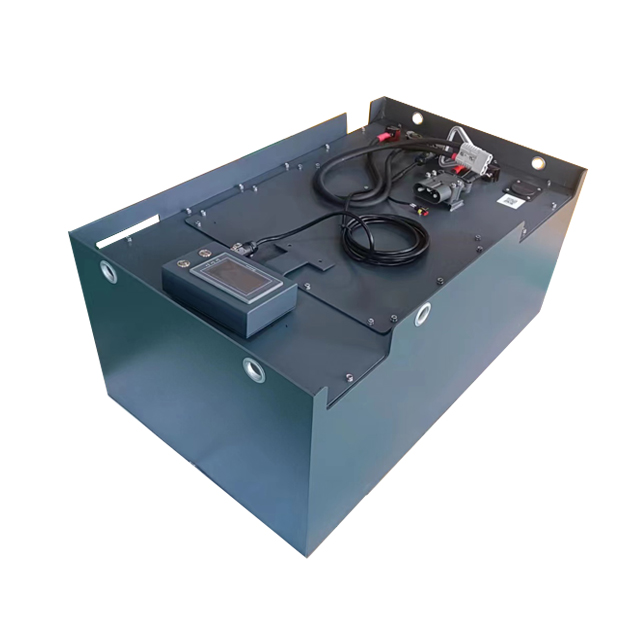

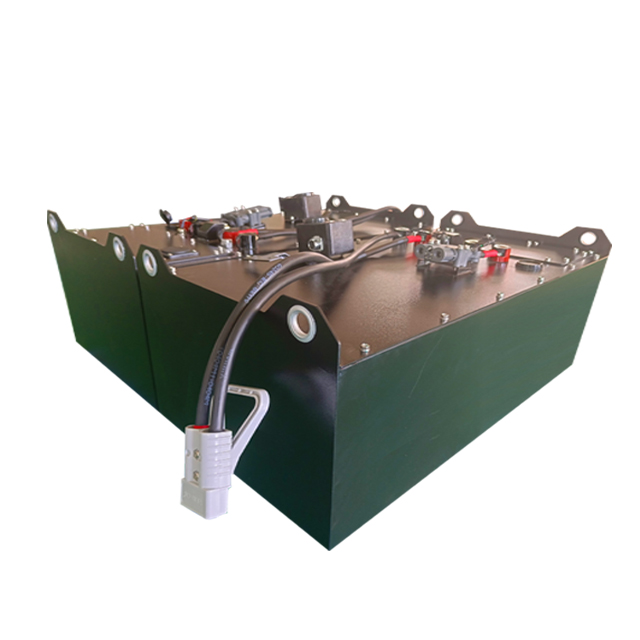

Funciones de seguridad aumentadas: el sistema inteligente de gestión de baterías (BMS) facilita el monitoreo en tiempo real y múltiples mecanismos de seguridad para una protección mejorada.

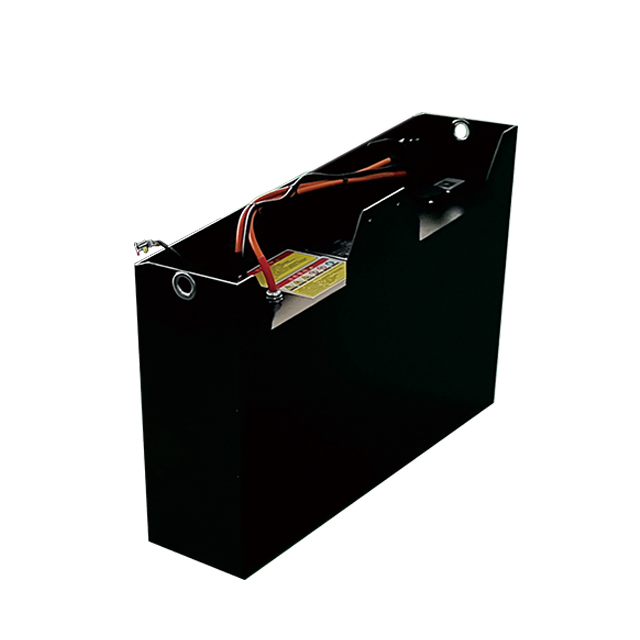

Avances y avances en las tecnologías Qianhang

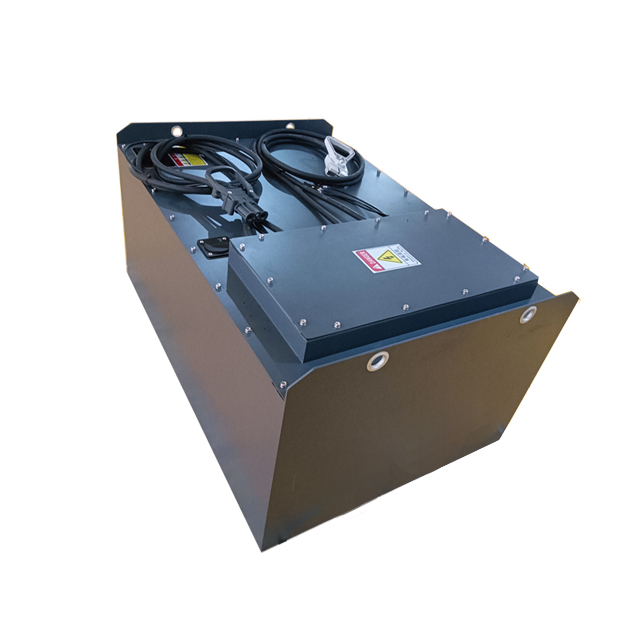

En un intento por aumentar la eficiencia, la seguridad y las ganancias finales de las baterías, las corporaciones están realizando inversiones sustanciales en investigación y desarrollo de tecnología Qianhang. Por ejemplo, Qianhang es pionero en la creación de baterías para montacargas resistentes a la congelación diseñadas para entornos de almacenamiento en frío. Estas baterías, con configuraciones internas y externas innovadoras, están protegidas contra el agua y la condensación, manteniendo temperaturas óptimas para una descarga constante. Este avance eleva notablemente el rendimiento y la seguridad de los montacargas y, en última instancia, garantiza la eficacia operativa y el rendimiento.

Ciertos fabricantes están profundizando en soluciones de baterías de vanguardia, como capacidades de carga rápida, alternativas de alta densidad de energía, sistemas avanzados de gestión de baterías (BMS) y más, con el potencial de redefinir los estándares de la industria. Además, a medida que aumentan las demandas del mercado, cumplir los objetivos de productividad se vuelve más arduo, lo que alimenta la tendencia de automatizar los equipos de montacargas en los entornos de almacén contemporáneos. En consecuencia, el desarrollo de sistemas de baterías de litio para carretillas elevadoras automáticas se vuelve cada vez más imperativo.

Más allá de la innovación y la excelencia de los productos, los productores de baterías de litio para montacargas están empleando diversas estrategias para navegar en un panorama en constante evolución. Por ejemplo, empresas como Qianhang están ampliando sus capacidades de fabricación a través de métodos de producción modular y reduciendo los tiempos de entrega mediante el almacenamiento previo de inventario en almacenes en el extranjero, además de establecer centros de servicios localizados. Además, algunas empresas están mejorando el recorrido del cliente ofreciendo sesiones de formación sobre el uso óptimo de la batería. Estas maniobras estratégicas contribuyen colectivamente a mejorar la eficiencia y reducir los costos generales de propiedad.

En conclusión, si bien los gastos iniciales y los rendimientos fluctuantes de la inversión pueden plantear obstáculos temporales para las empresas que están considerando la transición, la tecnología de iones de litio se erige como la piedra angular del futuro del manejo de materiales, presentando claras ventajas en el rendimiento y los gastos generales de propiedad. Con los avances continuos y la expansión de las tecnologías de litio, anticipamos nuevas mejoras que redefinirán el panorama del sector de manipulación de materiales. Al adoptar estas innovaciones, las empresas pueden obtener una mayor eficiencia, mejores medidas de seguridad, mejores prácticas de sostenibilidad y una mayor rentabilidad, posicionándose como líderes en el ámbito del manejo de materiales en constante evolución.

Para detalles adicionales y consultas, por favor visite: www.qhlithiumbattery.com o envíenos un correo electrónico a: helen@qhlithiubateria.com

Español

Español